Research

The Tam Shiu Anatomical Modelling Laboratory

We provide clinical and research support consultation and production service in medical 3D printing. Established in 2018, the laboratory now provides service to more than 300 patients each year with complex pathologies requiring specialized 3D digital technology for intervention planning. The service is doctor led with an emphasis on rapid turnover, clinical relevance, quality, and clinical validation mandated in the production workflow. We encourage utilization of this facility for all pathoanatomically complex structural diseases from routine cases to the most unusual and innovative clinical situations. We offer specialist led service for orthopaedic cases which typically cover 60% of our load and collaborative consultation, design, and production for all other medical specialities in the remaining 40% of cases.

Our scope of service covers:

- Image segmentation and 3D modelling

- Patient specific 3D models for visualization of disease pathoanatomy

- Patient specific instruments

- Teaching and illustrative models

- Medical devices innovation

- Designing of patient specific implants

The anatomical modelling lab is supported by a generous donation from the Tam Shiu Charitable Foundation and HKU research funding. Our mission is to provide rapid quality service while minimising financial burden to entitled users. Our primary service target includes:

- All Hong Kong public and private hospitals

- Orthopaedic and all medically related specialities

- Allied health

- Medical devices innovation partners

- Collaboration with other academic units

Our primary production capability includes:

- Polymer Fused deposition modelling– single material ABS-M30i or Ultem 1010 (Stratasys)

- Polymer Selective laser sintering printer – single material PA-2200 (EOS)

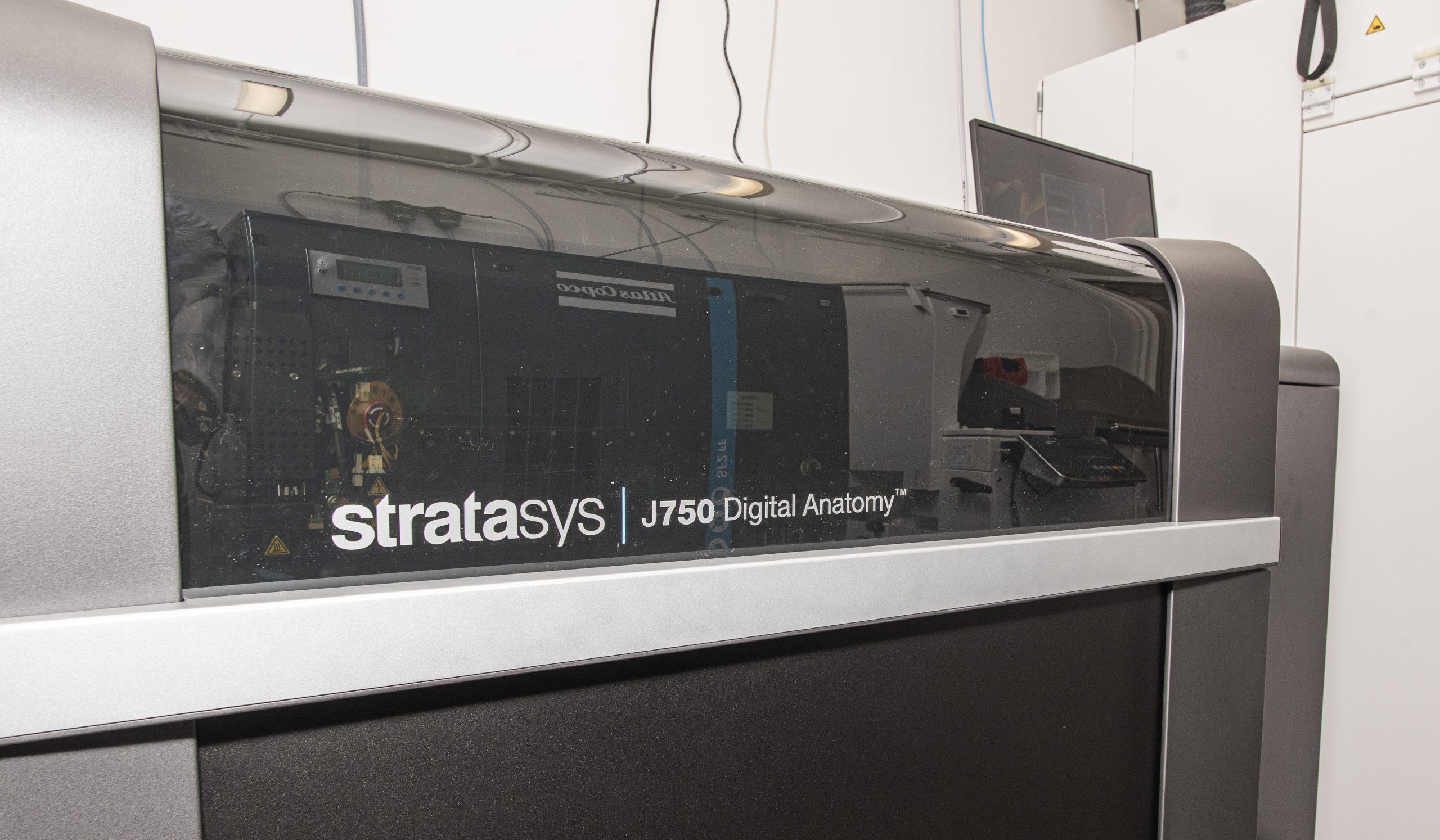

- Polymer Polyjetting – multiple materials (Stratasys J750 Digital anatromy)

- Metal – Outsourcing to industrial partner

a. For low cost, rapid turnover services

b. Simple anatomical models

c. Surgical Jigs and fixtures

d. Functional devices

a. High resolution and high durability models

b. Autoclavable surgical jigs and fixures

c. Functional devices

a. Complex anatomical models

b. Parts requiring transparency, rubber like consistency, and multiple colours

c. Functional parts for training and medical device innovation

d. Rapid turnover

For request of service and collaboration, please contact our secretary for more information: 3dprint@ortho.hku.hk

Case examples

Acetabular fracture model

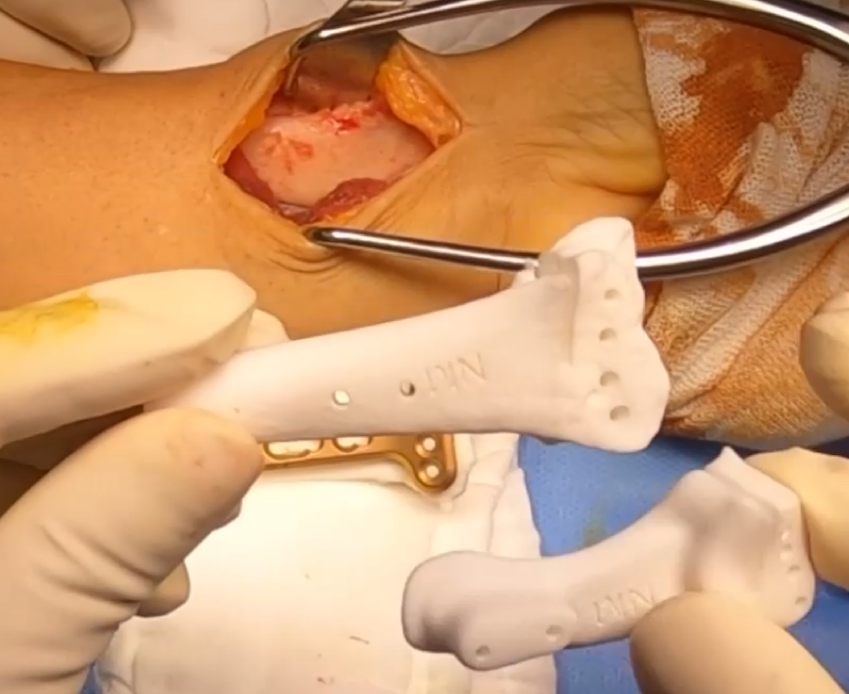

Distal radius osteotomy guides

Complex elbow fracture model

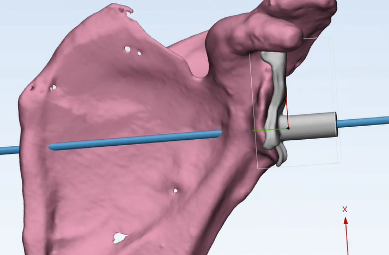

Shoulder replacement metaglene guides

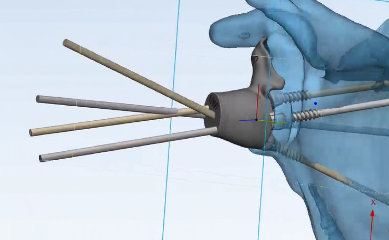

Spinal deformity patient specific pedicle guides

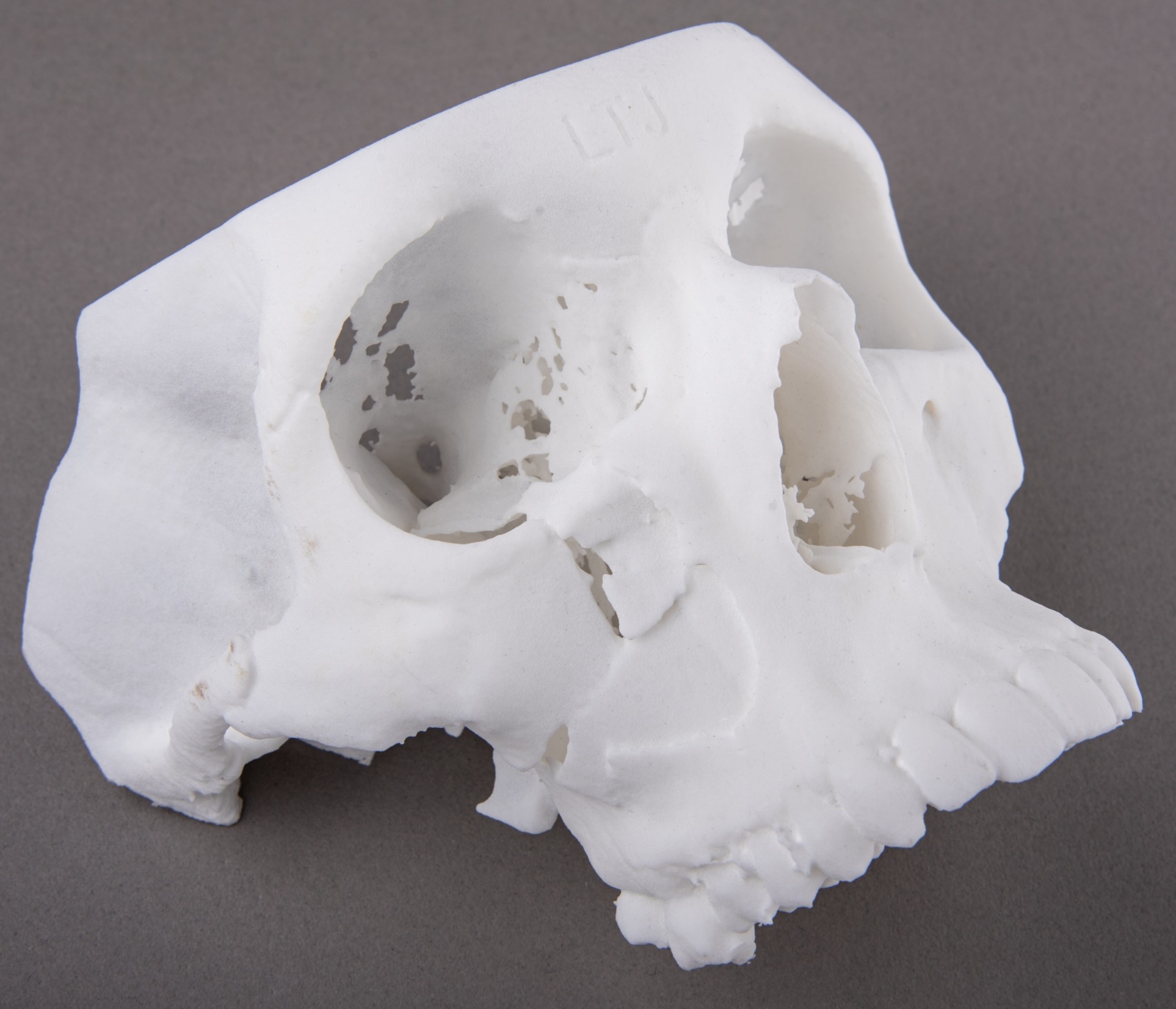

Facial fracture model

Free fibula flap mandibular reconstruction guides

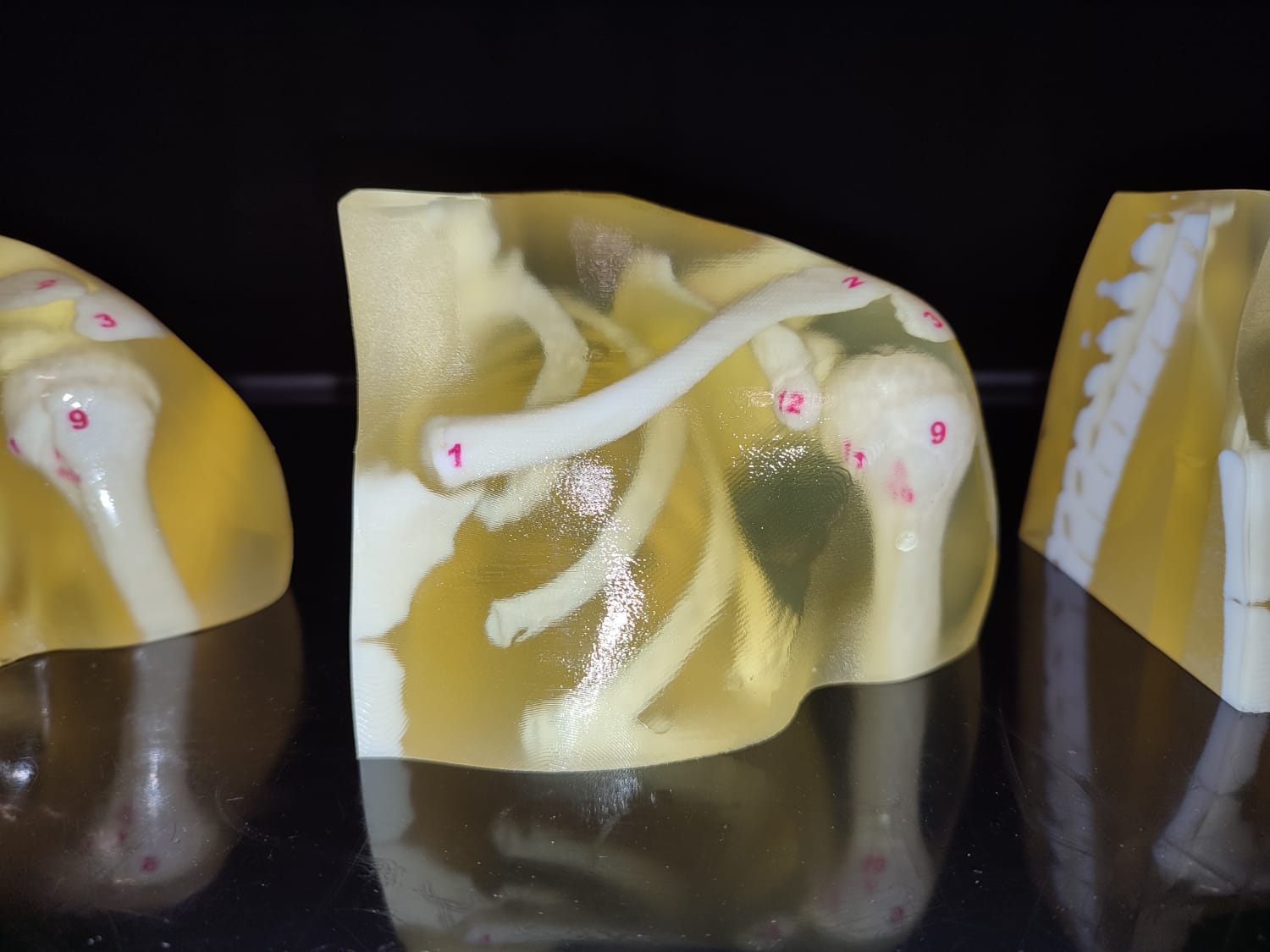

Cardiovascular intervention planning model

Nasal swab teaching model

Shoulder landmarks teaching model

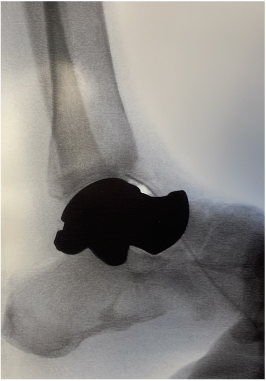

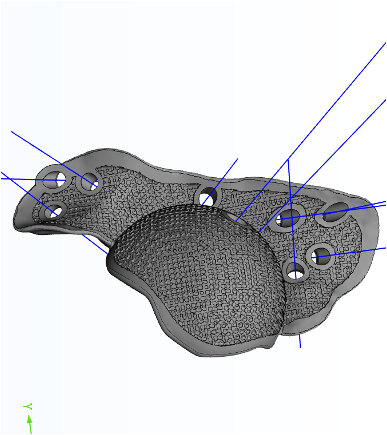

Patient specific talar implant

Revision hip prosthesis

Tumor mega-prosthesis