HKUMed unveils revolutionary nano bone material: High elasticity and strength expected to accelerate surgery and healing

13 October 2025

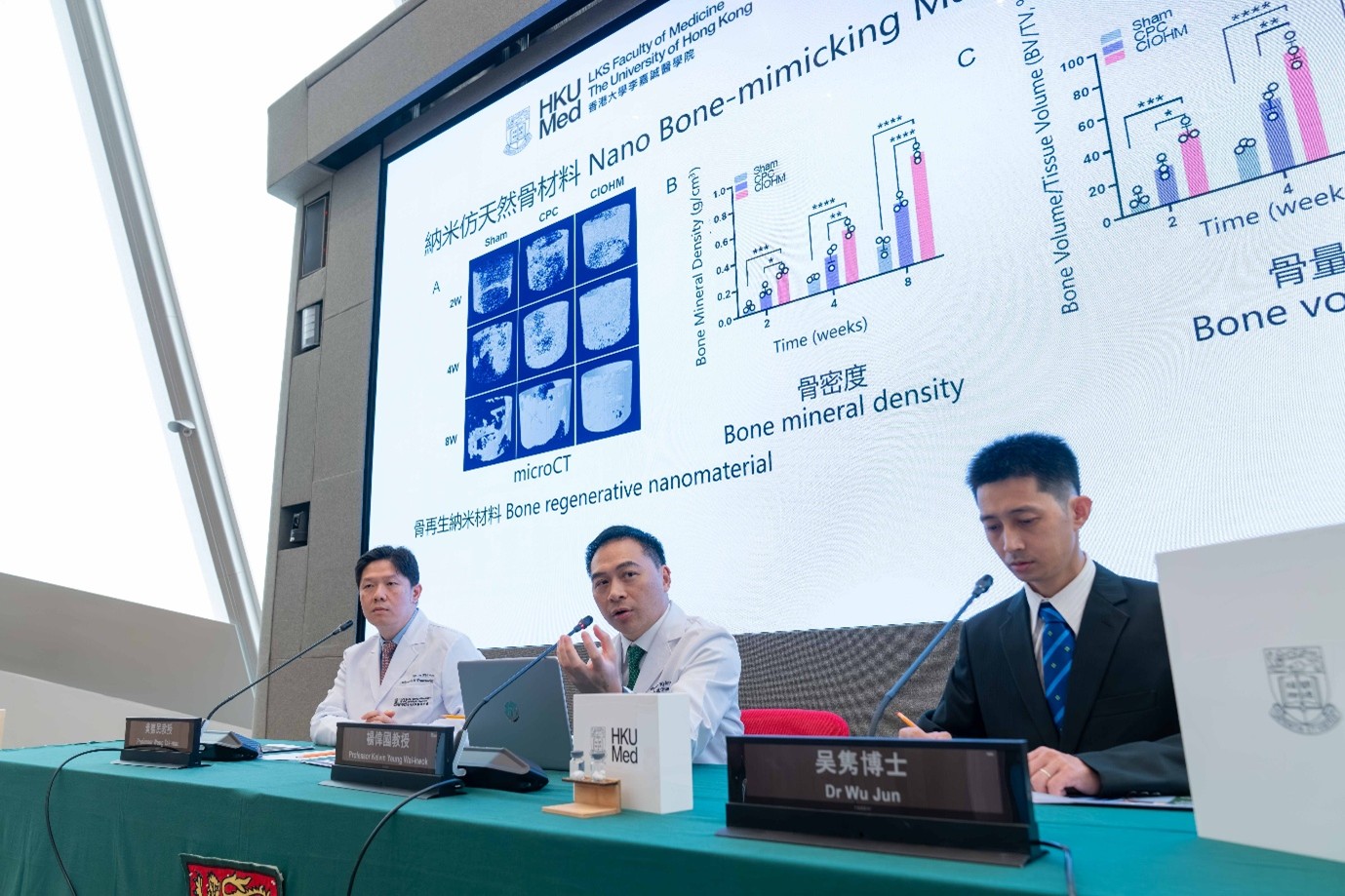

A research team from the Department of Orthopaedics and Traumatology at the University of Hong Kong’s LKS Faculty of Medicine (HKUMed) has successfully developed a novel elastic calcium phosphate material that mimics the structure of human bone. The material, dubbed ‘nano bone cement’, offers a promising alternative to traditional bone grafts in orthopaedic surgeries, which typically rely on harvesting tissue from the patient or a donor. Research and experimental results show that this innovative bone material provides robust mechanical support and accelerates healing in bone-defect cases.

The team plans to apply this technology to repair large segmental bone defects, potentially speeding up patient recovery and achieving optimal outcomes. The research findings were published in the journal Nature Communications link to publication, underscoring its scientific validity and effectiveness.

Current challenges in large segmental bone defect surgery

Professor Kelvin Yeung Wai-kwok, Ng Chun-man Professor in Orthopaedic Bioengineering, Department of Orthopaedics and Traumatology, School of Clinical Medicine, HKUMed, and project leader of the research, said treating large segmental bone defects typically requires bone grafting, which often involve autografts (from the patient’s own bone) or allografts (donated bone), which are scarce and carry significant risks. Autografts may lead to complications and collapse at the donor site, while autografts carry the risk of infection and immune rejection.

Traditional calcium phosphate bone materials are formed by mixing powders containing calcium and phosphorus with a liquid solution, resulting in a hardened solid through a self-setting reaction. Dr Wu Jun of the Orthopaedic Medical Centre at the University of Hong Kong-Shenzhen Hospital explained, ‘This material closely resembles the composition of natural bone, offering excellent safety and biocompatibility. Moreover, it can be freely shaped before hardening, making it one of the most promising options for bone repair.’

While traditional calcium phosphate artificial bone materials provide rigidity, their compressive strength falls short of that of human cortical bone. Their lack of elasticity makes them prone to fracturing in clinical use, and they struggle to adapt to minor deformations during daily activities, potentially leading to structural collapse and treatment failure. These limitations restrict the effectiveness and safety of existing bone graft technologies, underscoring the need to develop elastic bone materials to improve the success rate of large segmental bone repair.

Revolutionary triple ‘high performance’ nano material

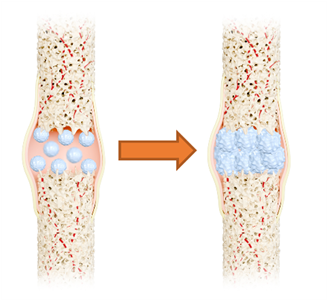

To address the shortcomings of existing calcium phosphate bone materials, the HKUMed research team utilised nano-cluster anchoring technology to successfully integrate the mechanical properties of organic flexible materials and inorganic rigid materials. This breakthrough resulted in a new ‘nano-artificial bone material’ (calcium phosphate cement (CPC)) that exhibits exceptional elasticity, toughness and strength.

Professor Yeung stated, ‘Our goal is to mimic the structure of natural bone, and this innovative nanomaterial closely resembles human bone. Its mechanical properties are closer to those of natural bone, thus enhancing patient comfort and mobility. It can be shaped into any form before the hardening stage, making it particularly suitable for repairing irregularly shaped or complex bone defects.’

Leveraging the material’s capacity to expand in volume after absorbing water, the team developed a new type of elastic microsphere capable of automatically filling bone defects. This innovation streamlines surgical procedures and improves treatment efficiency. ‘The new nanomaterial maintains maximum compressive strength after absorbing water and exhibits excellent elasticity, a property not found in current bone material. It forms a porous structure that promotes cell adhesion and integration with the material, supporting bone tissue regeneration. This advancement will benefit more patients, offering them new hope for returning to a normal life,’ added Professor Yeung.

Professor Wong Tak-man, Clinical Professor, Department of Orthopaedics and Traumatology, School of Clinical Medicine, HKUMed, believes this groundbreaking material innovation will have multiple benefits for orthopaedic treatment. He said: ‘The new technology significantly simplifies surgical procedures and reduces overall operation time. The material demonstrates exceptional strength, toughness and superior biocompatible properties. Apart from filling defects in complex orthopaedic surgeries, it can provide stability and promotes bone healing. It offers a more flexible, safe and efficient solution for orthopaedic and reconstructive surgery. Last but not least, it can expand its application in neurosurgery and dentistry in the near future.

About the research team

This research was led by Professor Kelvin Yeung Wai-kwok, Ng Chun-Man Professor in Orthopaedic Bioengineering, Department of Orthopaedics and Traumatology, School of Clinical Medicine, HKUMed, who also served as a corresponding author. Other corresponding authors were Professor Tang Ruikang from Zhejiang University; and Dr Wu Jun, from the University of Hong Kong-Shenzhen Hospital. The co-authors were Professor Wong Tak-man, from the Department of Orthopaedics and Traumatology, School of Clinical Medicine, HKUMed; Liu Feihong, from The University of Hong Kong-Shenzhen Hospital; and Dr Yao Shasha, from Sir Run Run Shaw Hospital, School of Medicine, Zhejiang University.

Acknowledgements

This research received support from multiple funding sources, including the National Key R&D Program of China, the Health and Medical Research Fund, and the Shenzhen Science and Technology Innovation Commission Research Fund.

More on:

港大醫學院首創革命性「納米仿天然骨材料」高彈性和強韌特點 縮短手術時間加快癒合

2025年10月13日

香港大學李嘉誠醫學院(港大醫學院)臨床醫學學院矯形及創傷外科學系科研團隊成功研發一種新型彈性磷酸鈣「納米仿天然骨」材料,可用於骨科手術,以替代傳統的自體骨和異體骨移植。研究及實驗結果顯示,該創新骨材料能提供足夠的力學支撐,並加快骨缺損的癒合。科研團隊計劃應用此技術於大段骨缺損的修復,有望加快患者的康復,達到理想效果。相關研究成果已於《自然通訊》期刊發表(按此瀏覽期刊文章),證明其科學性和有效性。

現時大段骨缺損手術的挑戰

帶領是次研發的港大醫學院臨床醫學學院矯形及創傷外科學系教授兼伍振民基金教授(骨科生物工程)楊偉國教授指出,大段骨缺損的治療通常需要進行骨移植,但自體骨(患者自身骨頭)和異體骨(他人捐贈骨頭)匱乏,且有較高併發症風險。例如自體骨可能導致供骨部位出現併發症和塌陷;異體骨則可能導致外源性感染和免疫排斥。

傳統的磷酸鈣骨材料由含鈣和磷的粉劑與水劑混合,經自我固化反應後形成堅硬的固體。香港大學深圳醫院骨科醫學中心吴隽博士解釋:「由於這種材料與天然骨的成分最為接近,具有極高的安全性和生物相容性,且在預固化階段可以任意塑形,是目前最有前景的骨修復材料。」

然而,傳統磷酸鈣人工骨材料雖然堅硬,但抗壓強度不及人體的皮質骨,且因缺乏彈性,在臨床使用上容易斷裂、骨骼亦較難適應日常活動的微小變形,可能發生塌陷而導致治療失敗,不適用於高負荷部位的修復。這些問題限制了現有骨移植技術的效果和安全性,因此研發具彈性的新型骨材料成為提升大段骨修復成功率的重要方向。

革命性三「高質」納米材料

針對目前磷酸鈣天工骨材料的不足,港大醫學院科研團隊利用納米簇錨點技術,成功融合有機柔性材料和無機剛性材料的力學特徵,研發出一種兼具高彈性、高韌性和高強度的磷酸鈣「納米仿天然骨材料」 (Calcium Phosphate Cement,CPC)。楊偉國教授表示:「我們的目標是模仿天然骨的結構,讓這種創新的納米材料更接近人類骨頭。它更貼近天然骨骼的力學特性,可提升患者的舒適度與活動能力。在預固化階段可塑造成任何形狀,能精準塑形並緊密貼合缺損部位,特別適合修復形狀不規則或位置複雜的骨缺損。」

研究團隊利用彈性磷酸鈣納米仿天然骨材料吸水後體積增大的特性,研發出一種可自動填充骨缺損的彈性微球,有助簡化手術流程並提升治療效率。楊偉國教授續指:「新型納米骨材質吸水後不僅能保持最大抗壓強度,還具備現時骨材料所沒有的良好彈性,形成多孔結構,有助於細胞與材料黏合,有利骨組織再生,將讓更多病患受益,重獲正常生活的希望。」

港大醫學院臨床醫學學院矯形及創傷外科學系臨床教授黃德民教授認為,這項突破性的材料創新,將為骨科治療帶來多重好處。他表示:「新技術可大幅簡化手術步驟,有效縮短整體手術時間;新材料在保持卓越彈性的同時,並擁有優異的強度與韌性,同時具有超卓的生物相容特性。除了能應用於複雜骨科手術中的缺損填補,更可提供穩固支撐並促進骨骼癒合,為骨科及整形外科手術提供更靈活、安全且高效的解決方案。我相信此材料將來可拓展至神經外科及牙科領域的應用。」

研究團隊

這項研究由港大醫學院臨床醫學學院矯形及創傷外科學系教授兼伍振民基金教授席(骨科生物工程)楊偉國教授領導並擔任通訊作者。其他通訊作者為浙江大學唐睿康教授和香港大學深圳醫院吴隽博士。共同作者為港大醫學院臨床醫學學院矯形及創傷外科學系臨床教授黃德民教授、香港大學深圳醫院劉飛宏和浙江大學醫學院附屬邵逸夫醫院姚沙沙博士。

鳴謝

此項研究獲得多項資助,包括國家重點研發計劃、醫療衞生研究基金、深圳市科技創新委員會研究基金。

更多內容